Industrial environments generate massive time-series data, but industrial data historian systems often stop at storage. As a result, data remains siloed, reporting is manual and critical operational trends are identified too late.

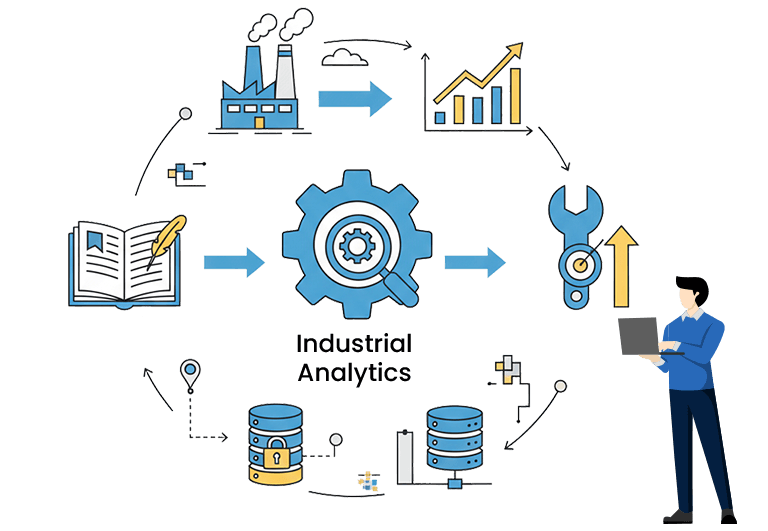

We transform stored data into intelligence through custom industrial software development. By building a secure, scalable analytics layer on top of existing process historian software, powered by .NET industrial applications and cloud-native architecture, we deliver actionable insights, without disrupting current systems.

The client had already invested in enterprise-grade industrial historian software across multiple plants. While data capture was robust, the organization struggled to convert historical process data into insights usable by operations leaders and executive teams.

Infomaze implemented a modern industrial analytics platform that integrated seamlessly with existing historians. The solution unified data across systems, automated reporting, and delivered role-based dashboards—creating a scalable foundation for operational intelligence and future AI initiatives.

Key outcomes included faster decision-making, reduced manual reporting, and improved enterprise-wide visibility.

The client operates within a highly complex industrial environment where multiple assets, production lines and processes generate continuous operational data. Their ecosystem included enterprise-grade industrial historian software already deployed across plants and capturing years of historical process data.

Despite having robust historians in place, the organization lacked a unified way to analyze, visualize and extract intelligence from this data at scale. Engineering teams relied on manual queries, leadership lacked consolidated views, and operational insights were fragmented across systems.

Although data was stored in the industrial data historian, teams had no intuitive way to analyze long-term trends across assets, processes, or time periods.

Operational data lived in multiple historian platforms, which make correlation across systems and processes time-consuming and error-prone.

Engineers manually extracted data for reports, leading to delays, inconsistencies, and high dependency on specialized resources.

There was no single platform for KPIs, performance tracking, energy efficiency or anomaly monitoring across roles.

While data existed, it did not translate into decisions. Root cause analysis, benchmarking, and continuous improvement initiatives lacked reliable analytical support.

The client needed a solution that enhanced their process historian software through secure integration, analytics and visualization.

We designed a modular, cloud-ready platform focused on industrial process historian integration, analytics, and scalability. The architecture was purpose-built for industrial environments using .NET process historian integration and Azure-native services.

This approach allowed the organization to modernize historian data usage while preserving existing OT investments.

We implemented a robust integration layer that securely connects to existing historians, including:

This ensured enterprise-grade industrial process historian integration without impacting historian performance or plant operations.

Historian data varies widely across vendors and systems. Our processing layer handled:

This created a single source of operation for analytics, reporting, and visualization, critical for scalable industrial application development.

We developed role-specific dashboards tailored for:

Users could explore years of historian data visually, reducing analysis time from hours to seconds.

The platform introduced automated reporting that:

This significantly reduced reliance on manual historian queries and spreadsheets.

By combining normalized historian data, the system enabled:

Teams could benchmark performance across:

This transformed historical data into a continuous improvement engine.

The solution was developed using .NET industrial applications and deployed via Azure Web Apps, aligning with modern Azure Industrial IoT principles.

The architecture supports future machine learning models trained on historical data, powered by Azure integration services.

The engagement delivered measurable value across teams and operations:

Central access to real-time and historical operational data

Insights delivered instantly for confident, data-driven actions

Manual engineering reports significantly reduced through automation

Clear performance insights shared across teams and roles

Future-ready analytics built on existing infrastructure systems

For CIO, CXO and senior executives, industrial analytics initiatives are not about dashboards or technology stacks, they are about business outcomes, risk reduction, and long-term competitiveness.

This transformation enabled leadership to:

By converting historian data into executive-level intelligence, the organization moved from reactive decision-making to proactive operational leadership.

Infomaze brings a unique blend of industrial domain understanding and enterprise-grade software engineering.

What sets Infomaze apart:

We understand how industrial environments operate—OT systems, historians, data integrity constraints, and plant-critical performance requirements.

We enhance existing industrial and process historian software rather than replacing it, protecting prior investments and minimizing operational risk.

Our solutions are built using proven .NET industrial applications and Azure-native architectures, ensuring scalability, security, and long-term maintainability.

Every solution is tailored to real operational workflows—no one-size-fits-all dashboards or generic analytics layers.

Our architectures are designed not just for reporting, but for advanced analytics, AI enablement, and continuous improvement at enterprise scale.

Infomaze acts as a technology partner, helping industrial organizations turn complex historian data into measurable business value.

Industrial historians are exceptional at capturing data but intelligence emerges only when that data is contextualized, visualized, and analyzed. Through deep expertise in .NET development, industrial historian software, and cloud-native design, Infomaze helped the client unlock the true value of their historical process data.

By delivering a scalable analytics layer on top of existing historians, we bridged the gap between raw time-series data and operational excellence, creating a future-ready platform for advanced analytics and AI-driven insights.

Partner with Infomaze to build secure, scalable and insight-driven industrial solutions that turn historian data into real business outcomes. Let’s transform your data into decisions.

Let us know! Our product experts can configure the best solution for your business.